- Polymer materials

- New energy industry

- Photovoltaic industry

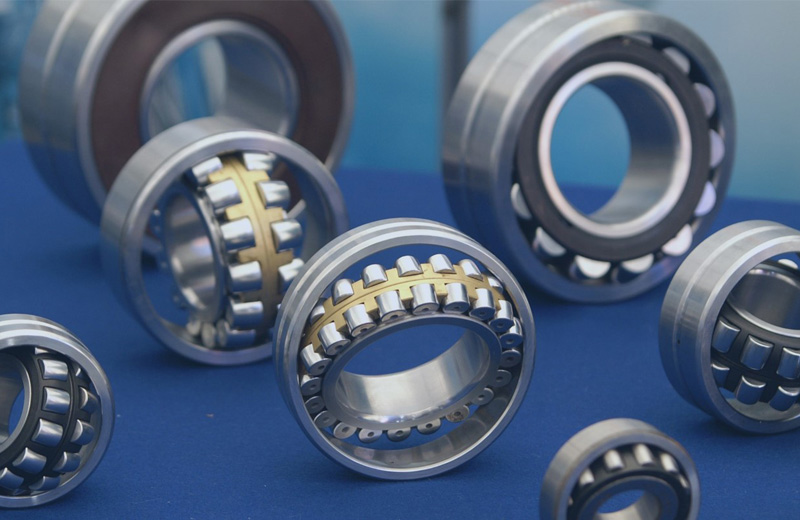

- Bearing Industry

- Aluminum profile industry

- Flooring Industry

- Fertilizer industry

- Steel Industry

- Power Industry

- T800-MINI

- Construction Machinery Industry

- I-shaped wheel industry

- Metal processing industry

- Chemical industry

- 3C Industry

- Tire Industry

- Cable industry

- Welding wire disc industry

- Construction Industry

- Rail Transit Industry

- Sanitary Industry

- Chemical Engineering Industry

- Automobile Industry

- Agriculture

- Cold Chain Industry

- Household Appliance Industry

- FMCG Industry

- Textile Industry

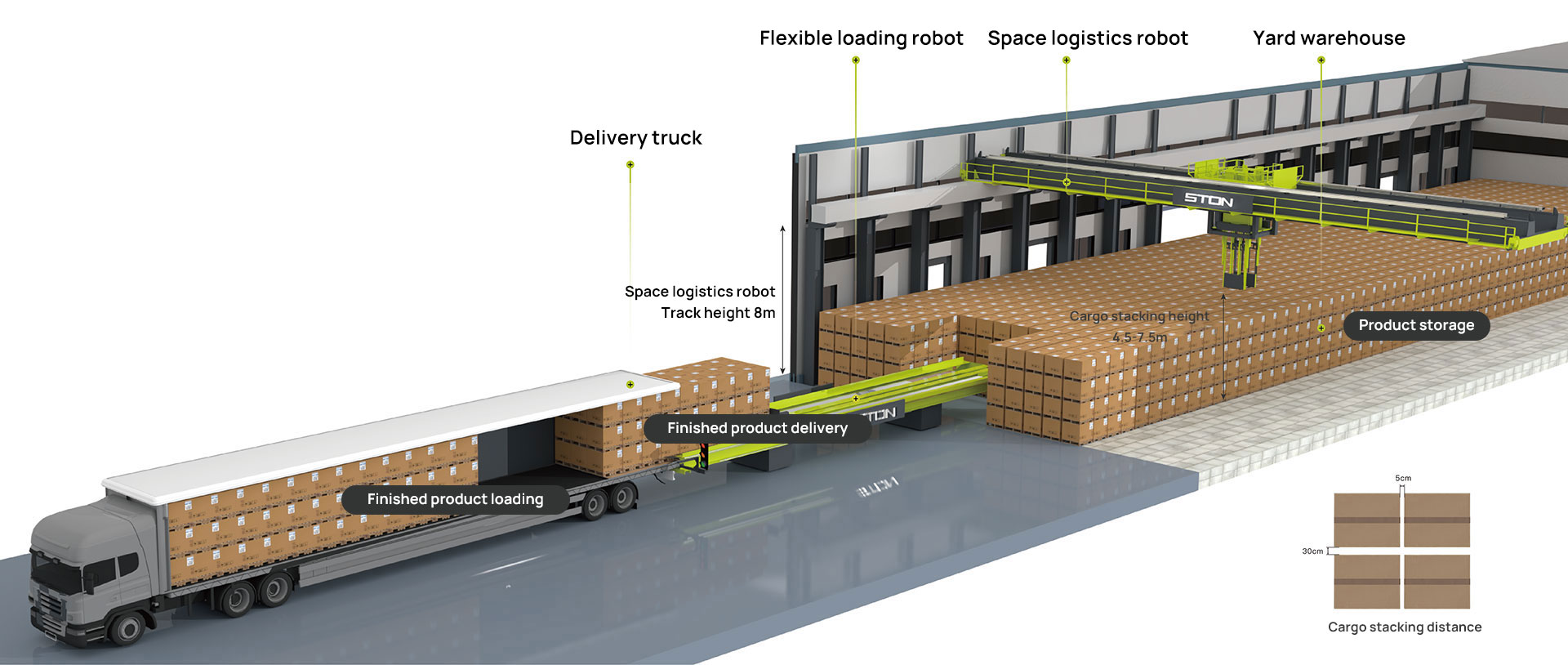

Space logistics robot product family map Transferring traditional ground warehousing to the air, completely breaking away from the constraints of the ground, using a dimensionally reduced cabinet-less control system to crush traditional ground logistics methods in terms of cost and efficiency.

This will change the warehousing pattern in the logistics field. TURN AN EMPTY SPACE INTO A THREE-DIMENSIONAL WAREHOUSE IN SECONDS

This will change the warehousing pattern in the logistics field.

Double arm series

-

T800 type

T800 type- Double arm type

- Maximum span: 30 meters

- Walking distance: 200 meters

- Load: 5 tons (maximum)

- Arm travel: 4.8~7.5 meters

- Factory height: 9~13 meters

-

T800-MINI type

T800-MINI type- Double arm type

- Maximum span: 15 meters

- Walking distance: 200 meters

- Load: 3 tons (maximum)

- Arm travel: 1.8~4.5 meters

- Factory height: 3~8 meters

Single arm series

-

T800-2 type

T800-2 type- Single arm type

- Maximum span: 30 meters

- Walking distance: 200 meters

- Load: 3 tons (maximum)

- Arm travel: 2~4 meters

- Factory height: 6~8 meters

-

T800-6 type

T800-6 type- Single arm sleeve type

- Maximum span: 18 meters

- Walking distance: 200 meters

- Load: 0.3 tons (maximum)

- Arm travel: 3.5 meters

- Factory height: 7~13 meters

-

Lane type space logistics robot

H3000 type

H3000 type- Lane type space logistics robot

- Maximum span: 30 meters

- Walking distance: 200 meters

- Load: 1 ton (maximum)

- Arm travel: 9 meters

- Factory height: 4~11 meters

-

Servo three-dimensional warehouse

S1500 type

S1500 type- Servo three-dimensional warehouse

- Height: 3~40 meters

- Load: 50~10000kg

- Horizontal speed: 3~200 meters/minute

- Lifting speed: 3~60 meters/minute

-

Loading robot

LAP35 type

LAP35 type- Loading robot

- Total length: 16.5 meters

- Loading chain plate length: 13.5 meters

- Loading width: 2.25~2.5 meters

- Loading height: 1.15~1.65 meters

- Load: 30 tons (maximum)

- Conveying speed: 15 meters/minute

The reform of the times led by space logistics robots Servo technology + Cabinetless control system + AI algorithm The space logistics robot used for yard logistics sorting completely subverts the traditional manual forklift sorting model and fills the gaps at home and abroad. It adopts the idea of ??dimensionality reduction to package the most advanced technology and make a very complex industrial robot system. It has become a standard product that is as simple and easy to use as home appliances, crushing traditional logistics methods in terms of cost and efficiency.

- Low infrastructure costs and standardized application scenarios

It is suitable for various forklift-type warehouses, cargo yards, and storage yards. In principle, it only requires an open space, and it is plug-and-play. There is no need to stop work and production, because the infrastructure requirements for the site are very low: standard factory buildings, simple greenhouses , or even an outdoor open space can be built into an unmanned warehouse, greatly reducing the cost of infrastructure.

- Three-dimensional storage without shelves

Utilize carriers such as smart frames, smart racks, pallets, and turnover boxes to realize self-stacked three-dimensional storage in a dense array of goods.

- Dense array storage, 3 times the storage capacity of forklift yards

The goods are stacked in a dense array (the distance between adjacent goods in each column is 30cm, and the distance between each row of goods is 5cm). There is no need to reserve forklift passages and turnover space. The stacking height of goods is 4.5~7.5 meters (the comprehensive storage capacity is 3 times that of an ordinary truck yard). times or more).

AIR WAREHOUSE

Comparison of comprehensive costs between aerial sorting smart warehouses and traditional methods

| 類別 | 項目 | 叉車平庫 | 自動立庫 | 空中物流機(jī)器人 |

|---|---|---|---|---|

|  |  | ||

| 需求與規(guī)格 | 托盤個數(shù)(個) | 10,000 | 10,000 | 10,000 |

| 托盤規(guī)格 | 1200x800x1000 | 1200x800x1000 | 1200x800x1000 | |

| 地面面積使用率 | 39% | 50.00% | 80% | |

| 層數(shù) | 3 | 13 | 6 | |

| 巷道寬(米) | 4 | 1.5 | 0.3 | |

| 單位貨架長(米) | 3.14 | 3.14 | 1.20 | |

| 單位貨架寬(米) | 1.3 | 1.3 | 0.85 | |

| 單位貨架托盤數(shù)(個) | 3 | 3 | 1 | |

| 貨架面積(平米) | 4536 | 1047 | 1700 | |

| 基建投資 | 總建筑面積 | 11,513 | 2,093 | 2,125 |

| 建筑單價 | 0.20 | 0.45 | 0.20 | |

| 建筑成本(萬) | 2,303 | 942 | 425 | |

| 單位用地成本(萬/畝) | 100 | 100 | 100 | |

| 總用地成本(萬) | 1,727 | 314 | 319 | |

| 基建總成本(萬) | 4,030 | 1,256 | 744 | |

| 貨架單位成本(元) | 350 | 350 | 500 | |

| 貨架投資(萬元) | 350 | 350 | 0 | |

| 堆垛機(jī)單位成本(萬) | 0 | 280 | 300 | |

| 堆垛機(jī)投資(萬元) | 0 | 1,400 | 300 | |

| 硬件投資 | 其他配套設(shè)各(輸送及控制系統(tǒng))(萬元) | 0 | 1,500 | 200 |

| 信息系統(tǒng)(倉儲管理系統(tǒng)軟硬件)(萬元) | 150 | 150 | 50 | |

| 叉車單位成本(萬元) | 35 | 35 | 35 | |

| 叉車投資(萬元) | 525 | 105 | 105 | |

| 硬件總投資(萬元) | 1,025 | 3,505 | 1155 | |

| 人力(個數(shù)) | 25 | 6 | 2 | |

| 人力成本(萬/年) | 250.0 | 60.0 | 20.0 | |

| 能耗費用(萬/年) | 46.9 | 72.4 | 24.5 | |

| 硬件年維護(hù)費用(萬元/年) | 40 | 92 | 17 | |

| 總成本 | 合計(萬元) | 11,792 | 9,749 | 3,129 |

- Space logistics robot VS Forklift warehouse

To store 10,000 1200x1000mm pallets, the forklift warehouse covers an area of ??11,000 square meters, the space robot only has 2,000 square meters, the manpower is only 10% of the forklift, the energy consumption is half of the forklift, and the comprehensive cost of use in 20 years is 1/4 of the forklift. .

Covered areaManpowerEnergy consumptionoverall costs - Space logistics robot VS Three-dimensional warehouse

To store 10,000 1200x1000mm pallets, the area of ??the three-dimensional warehouse and the space robot are both about 2,000 square meters. The manpower is 1/3 of the three-dimensional warehouse, the equipment investment is 30% of the three-dimensional warehouse, and the energy consumption is 1/3 of the three-dimensional warehouse. Equipment maintenance is 1/5 of that of a three-dimensional warehouse, and the comprehensive cost of use over 20 years is 1/3 of that of a forklift.

Energy consumptionEquipment maintenanceEquipment investmentoverall costs

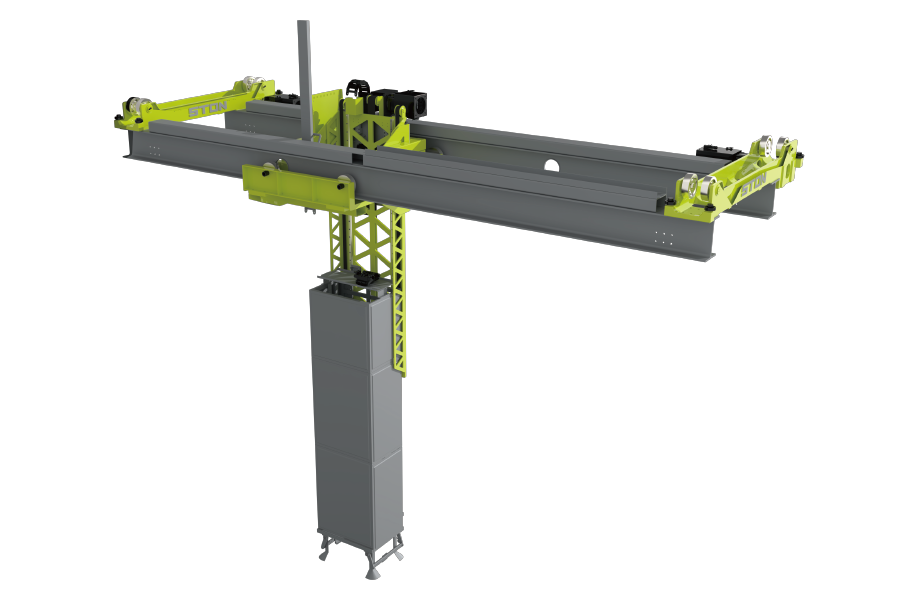

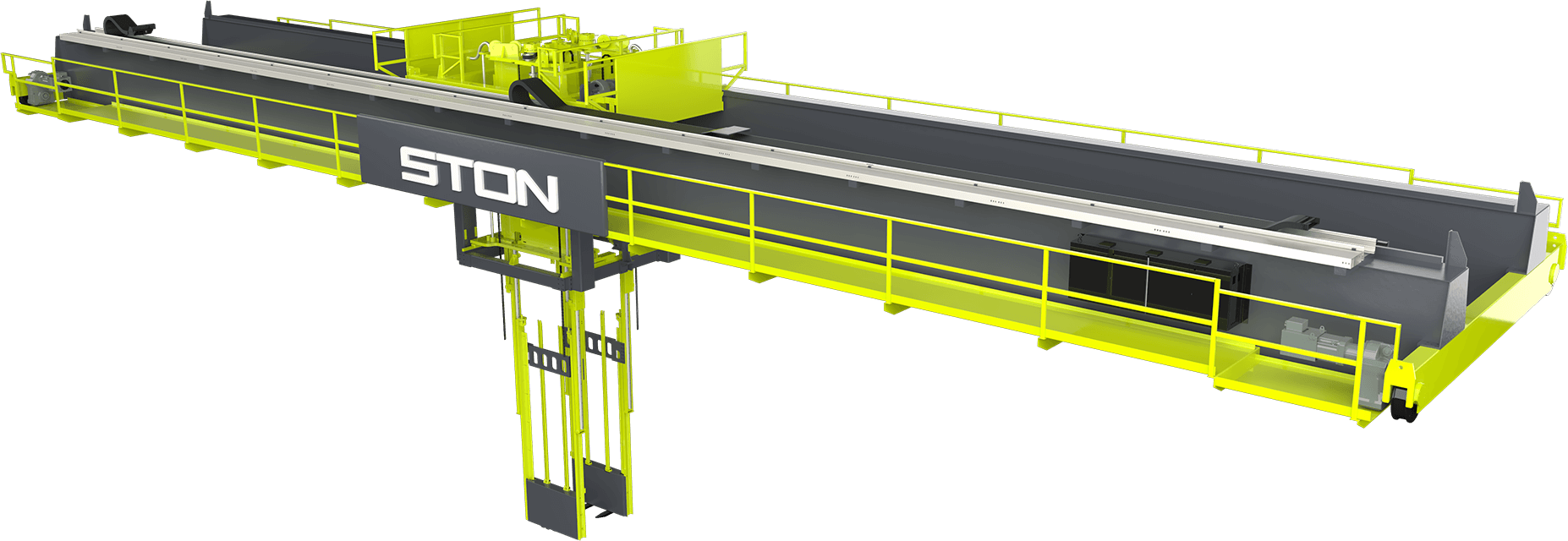

T800 double-arm space logistics robot

- 9~13 m

Factory height

- 5 t

maximum load

- 30 m

maximum span

- 4.8~7.5 m

arm stroke

-

The fastest delivery time is one month

The fastest delivery time is one monthTurn an empty space into a three-dimensional warehouse in seconds

-

Cabinetless Control System?

Cabinetless Control System?Condensing the bulky electrical control cabinet into the chip, eliminating the need for wiring, programming and operation

-

Significant cost reduction

Significant cost reductionThe cost of hardware investment is 1/3 of an ordinary forklift warehouse, and the annual usage cost is 1/10 of an ordinary forklift warehouse.

-

Warehousing capacity greatly increased

Warehousing capacity greatly increasedThe floor space of the aerial sorting smart warehouse is 1/5 of that of an ordinary forklift warehouse.

Applicable packaging

Applicable packaging | Maximum load | 5T |

|---|---|

| Installed power | 110KW |

| X-axis maximum travel | 200m |

| X-axis movement speed | 200m/min |

| X-axis acceleration | 0.5m/s2 |

| Y-axis maximum travel | 27m |

| Y-axis movement speed | 90m/min |

| Y-axis acceleration | 1m/s2 |

| Z-axis maximum travel | 6m |

| Z-axis movement speed | 30m/min |

| Z-axis acceleration | 1m/s2 |

| Repeatability | ±5mm |

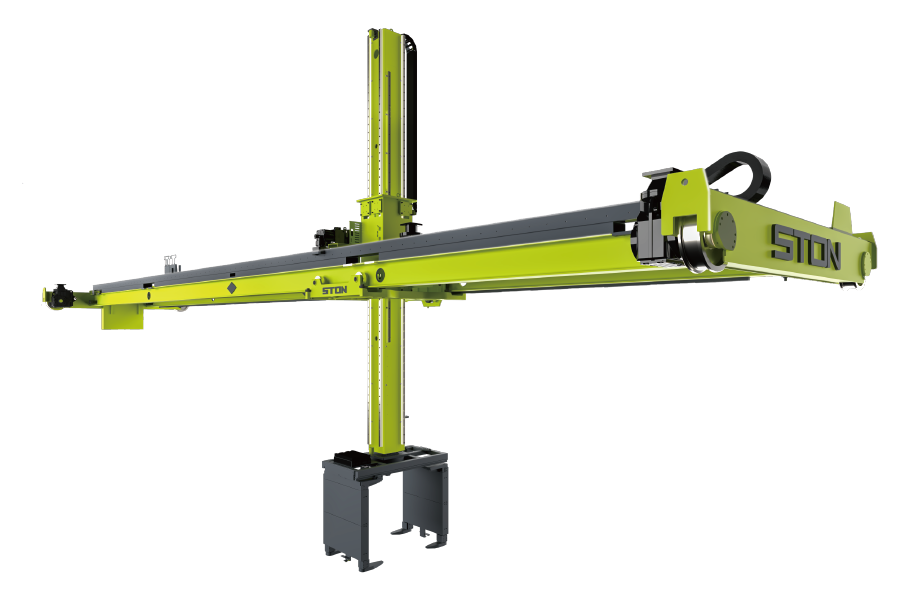

T800-MINI double-arm space logistics robot

Condensing the advantages of the T800 model, it is specially designed for low-rise factories. No factory building modification is required, and it can be used with only a floor height of 3 to 8 meters. The investment is small and the return is quick. It is especially suitable for the fast-moving consumer goods industry.

- 3~5 m

Factory height

- 3 t

Maximum load

- 15 m

maximum span

- 1.8~4.5 m

arm stroke

-

The fastest delivery time is one month

The fastest delivery time is one monthTurn an empty space into a three-dimensional warehouse in seconds

-

Cabinetless Control System?

Cabinetless Control System?Condensing the bulky electrical control cabinet into the chip, eliminating the need for wiring, programming and operation

-

No need for rail-bearing beams

No need for rail-bearing beamsSpecially designed for low-rise factories, direct installation on the ground reduces factory renovation costs.

-

Particularly suitable for FMCG industry

Particularly suitable for FMCG industryLow factory building, small span, compact space

Applicable packaging

Applicable packaging | Series | MINI3 | MINI5 | MINI8 |

|---|---|---|---|

| Maximum load | 1T | 1.5T | 3T |

| Installed power | 50KW | 60KW | 80KW |

| X-axis maximum travel | 200m | 200m | 200m |

| X-axis movement speed | 120m/min | 120m/min | 120m/min |

| X-axis acceleration | 0.5m/s2 | 0.5m/s2 | 0.5m/s2 |

| Y-axis maximum travel | 12m | 12m | 12m |

| Y-axis movement speed | 60m/min | 60m/min | 60m/min |

| Y-axis acceleration | 1m/s2 | 1m/s2 | 1m/s2 |

| Z-axis maximum travel | 1.8m | 3m | 4.5m |

| Z-axis movement speed | 24m/min | 24m/min | 24m/min |

| Z-axis acceleration | 1m/s2 | 1m/s2 | 1m/s2 |

| Repeatability | ±5mm | ±5mm | ±5mm |

| 廠房最小高度 | 3m | 5m | 8m |

T800-2 one-handed space logistics robot

The main body is integrally formed from cast steel, which not only has high strength and is not easily deformed, but also has a compact structure, a short production cycle, and a high degree of standardization of parts. A variety of clamps can be installed on the end of the single arm to enable it to cope with different application scenarios.

- 6~8 m

Factory height

- 3 t

Maximum load

- 30 m

maximum span

- 2~4 m

arm stroke

-

The fastest delivery time is one month

The fastest delivery time is one monthTurn an empty space into a three-dimensional warehouse in seconds

-

Cabinetless Control System?

Cabinetless Control System?Condensing the bulky electrical control cabinet into the chip, eliminating the need for wiring, programming and operation

-

Can be loaded directly into the vehicle

Can be loaded directly into the vehicleIt can realize warehouse entry and exit, stacking and loading, and full-process intelligent storage and transportation.

-

Optional customized gripper according to needs

Optional customized gripper according to needsApplicable to a variety of industries, warehouse types, and product packaging

Various gripper adaptations

Various gripper adaptations | Maximum load | 3T |

|---|---|

| X-axis maximum travel | 200m |

| X-axis movement speed | 200m/min |

| X-axis acceleration | 1m/s2 |

| Y-axis maximum travel | 28m |

| Y-axis movement speed | 90m/min |

| Y-axis acceleration | 1m/s2 |

| Z-axis maximum travel | 6m |

| Z-axis movement speed | 40m/min |

| Z-axis acceleration | 2m/s2 |

| Repeatability | ±3mm |

| Installed power | 60KW |

T800-6 single-arm sleeve type space logistics robot

The T800-6 space robot, which uses Jinshi gantry robot technology, not only stores and retrieves goods required for order fulfillment in plastic crates, totes, boxes and containers with high delivery rates, but can also manage everything from receiving to storage and picking, to Warehouse processes for packaging and shipping.

- 7~13 m

Factory height

- 0.3 t

Maximum load

- 18 m

maximum span

- 3.5 m

arm stroke

-

The fastest delivery time is one month

The fastest delivery time is one monthTurn an empty space into a three-dimensional warehouse in seconds

-

Cabinetless Control System?

Cabinetless Control System?Condensing the bulky electrical control cabinet into the chip, eliminating the need for wiring, programming and operation

-

Quick turnaround

Quick turnaroundSuitable for light, small volume and rapid sorting of multiple types of goods

-

Suitable for many industries

Suitable for many industries

Applicable packaging

Applicable packaging | Maximum load | 0.3T |

|---|---|

| X-axis maximum travel | 200m |

| X-axis movement speed | 180m/min |

| X-axis acceleration | 1m/s2 |

| Y-axis maximum travel | 15m |

| Y-axis movement speed | 90m/min |

| Y-axis acceleration | 1m/s2 |

| Z-axis maximum travel | 3.5m |

| Z-axis movement speed | 40m/min |

| Z-axis acceleration | 2m/s2 |

| Repeatability | ±3mm |

| Installed power | 60KW |

H3000 tunnel type space logistics robot

The robotic arm has a current loop force control algorithm that can automatically sense the status of the goods. The H3000 tunnel-type space robot was developed to solve the problems of low-rise factories with many categories and light cargo volume. It does not need to set up ground tracks, reduces factory renovations, and has extremely high efficiency in outbound delivery.

- 4~11 m

Factory height

- 1 t

Maximum load

- 30 m

maximum span

- 9 m

arm stroke

-

Cabinetless Control System?

Cabinetless Control System?Condensing the bulky electrical control cabinet into the chip, eliminating the need for wiring, programming and operation

-

Low investment

Low investmentNo need to install ground tracks, reducing factory building renovations

-

High income

High incomeLight load capacity and high delivery efficiency

-

Wide range of applications

Wide range of applicationsSuitable for light, small volume and rapid sorting of multiple types of goods

Applicable packaging

Applicable packaging | Maximum load | 0.3T |

|---|---|

| X-axis maximum travel | 200m |

| X-axis movement speed | 180m/min |

| X-axis acceleration | 1m/s2 |

| Y-axis maximum travel | 15m |

| Y-axis movement speed | 90m/min |

| Y-axis acceleration | 1m/s2 |

| Z-axis maximum travel | 3.5m |

| Z-axis movement speed | 40m/min |

| Z-axis acceleration | 2m/s2 |

| Repeatability | ±3mm |

| Installed power | 60KW |

Logistics yard terminator work site

- 1/5 Covered area

- 1/3 Hardware cost

- 1/10 Annual usage cost